Fabric inspection machines

Knitted fabric inspection machine

- Specially designed, automatic tension setting system inspection machine (With flat folded unit) for full lycra knitted fabrics.

- From roll to roll, from flat folded to roll, from roll to flat folded or from flat folded to flat folded working system

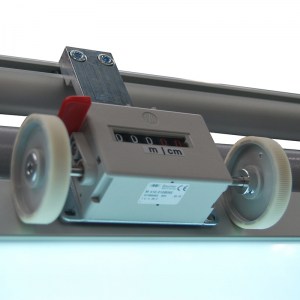

- It has upper and bottom lights and also can control measurement

- Sensitive rolling with automatic tension control

- Easy usage with the end of fabric stop photocell

- Optionally computerized data collecting and analyzing system

Woven fabric inspection machine

- Special design for full lycra woven fabrics

- From flat folded to roll, from roll to roll working system.

- It has upper and bottom lights and also can control measurement

- Easy usage with end of fabric stop photocell

- Tidy side wall with sensor control

- Sensitive rolling with automatic tension control

- Optionally computerized data collecting and analyzing system

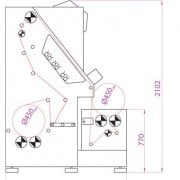

Rewinding machine P-3L

Rewinding/inspection machines with backlighting screen provide fast, easy quality control and measure fabric length.

A perfect choice for all textile manufacturers and businesses that deal with any kind of fabric.

The machine winds fabric from a roll placed inside the cradle on a core placed on a winding shaft.

Specifications:

Model: P-3L

Maximum width of fabric roll: 190 cm (74,80″)

Maximum roll diameter: 50 cm (19,69″)

Maximum rewindable weight of roll: 40[kg]

Voltage: 230[V]

Wattage: 0,18[kW]

Maximum winding speed: 50-60 m/min

Available models:

P-3L Standard rewinding machine with winding unit (from the roll cradle onto the tube), and length measurement device.

P-3L/R Additionally equipped with manual fabric end cutter OT-1/R.

P-3L/A Additionally equipped with semi-automatic fabric end cutter OT-1/A.

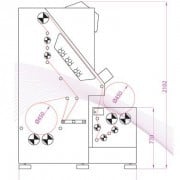

FABRIC REWINDING-INSPECTION MACHINE PP-3L

Rewinding/inspection machines with backlighting screen provide fast, easy quality control and measure fabric length.

A perfect choice for all textile manufacturers and businesses that deal with any kind of fabric.

The machine winds fabric from a roll placed inside the cradle on a core placed on a winding shaft.

Specifications:

Model: PP-3L

Maximum width of fabric roll: 190 cm (74,80″)

Maximum roll diameter: 50 cm (19,69″)

Maximum rewindable weight of roll: 40[kg]

Voltage: 230[V]

Wattage: 0,35[kW]

Maximum winding speed: 50-60 m/min

Screen size: 200 x 50 cm (78.74″ x 19.68″)

Screen: Yes

Сounter for yards or meters: Yes

Cradle for roll: Yes

Available models:

PP-3L Standard rewinding-inspection machine with backlight and winding unit (from the roll cradle onto the tube), and length measurement device.

PP-3L/R Additionally equipped with manual fabric end cutter OT-1/R.

PP-3L/A Additionally equipped with semi-automatic fabric end cutter OT-1/A.